Blog & Webinar articles.

Latest blogs & webinars

Finished – Unveiling Arkite VISION – Elevating manufacturing with revolutionary software

Why Attend? •Gain firsthand insights into the cutting-edge technology reshaping industrial manufacturing. •Discover how Arkite VISION can elevate your production processes, enhance product quality, and increase efficiency. •Interact with experts and get your questions...

Food for thought and inspiration

Let us guide you on your industry 4.0 journey

Learn all about lean manufacturing, poka yoke, process validation and digital work instructions.

Explore our extensive collection of blog articles and webinar recordings. Whether you’re looking to gain new insights, sharpen your skills, or simply indulge your intellectual curiosity, our content is here to support your personal and professional growth. Be sure to check back regularly as we continue to add fresh content and host exciting webinars.

Make sure to register if you’re looking for more in depth information on Arkite Platform and operator guidance.

Operator Guidance: A New Era in Automotive Manufacturing

Arkite, a leading provider of operator guidance instruction technology, is playing a pivotal role in this profound transformation of the automotive industry. Operator guidance instruction technology facilitates seamless human-machine interaction, ensuring efficient...

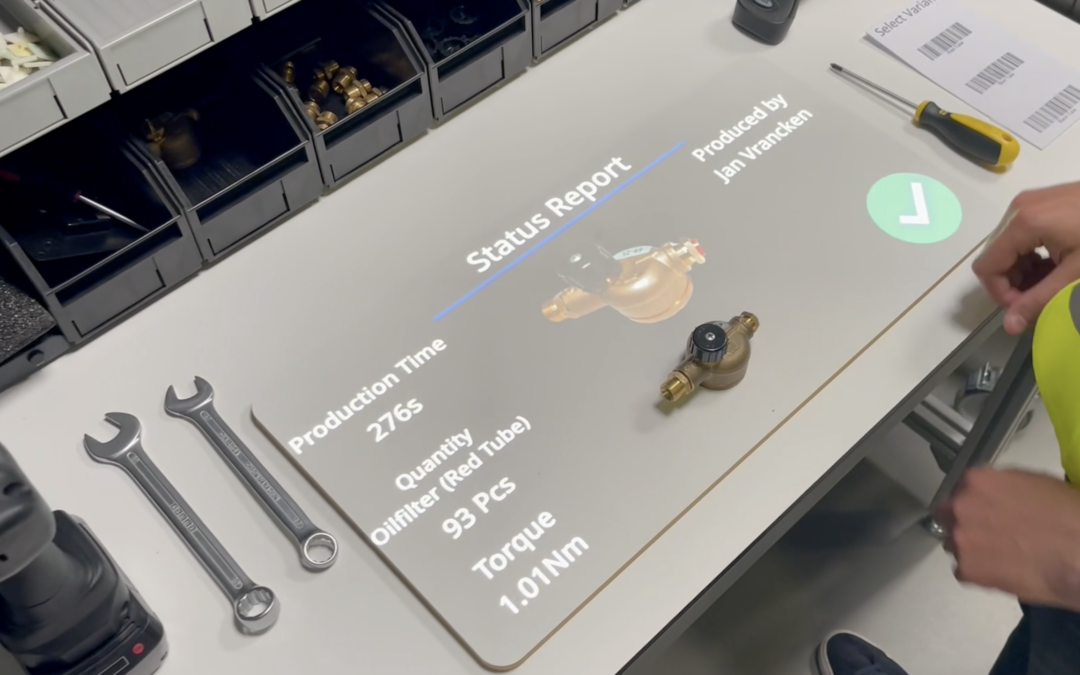

The benefits of using projected Augmented Reality for your digital work instructions

In today's fast-paced manufacturing environment, every business is looking for ways to improve their processes and increase efficiency. One way to achieve this is by using projectors in your manufacturing plant to provide your operators with digital work instructions,...

Is Projected Augmented Reality the answer to your manufacturing challenges?

Introduction In the fast-paced manufacturing environment, efficiency and productivity are key factors for businesses to stay ahead of their competition. To achieve this, companies are always searching for new technologies that can improve their processes. One such...

The challenge of finding skilled workers and how to face it with Arkite’s operator guidance platform

One of the main challenges many companies in the manufacturing industry face these days is the hiring of skilled operators. Unemployment rates are historically low, and there is a harsh competition among employers to bring in the best candidates. Whereas in the past...

Finished – Workstation of the future: projected augmented reality work instructions in manufacturing

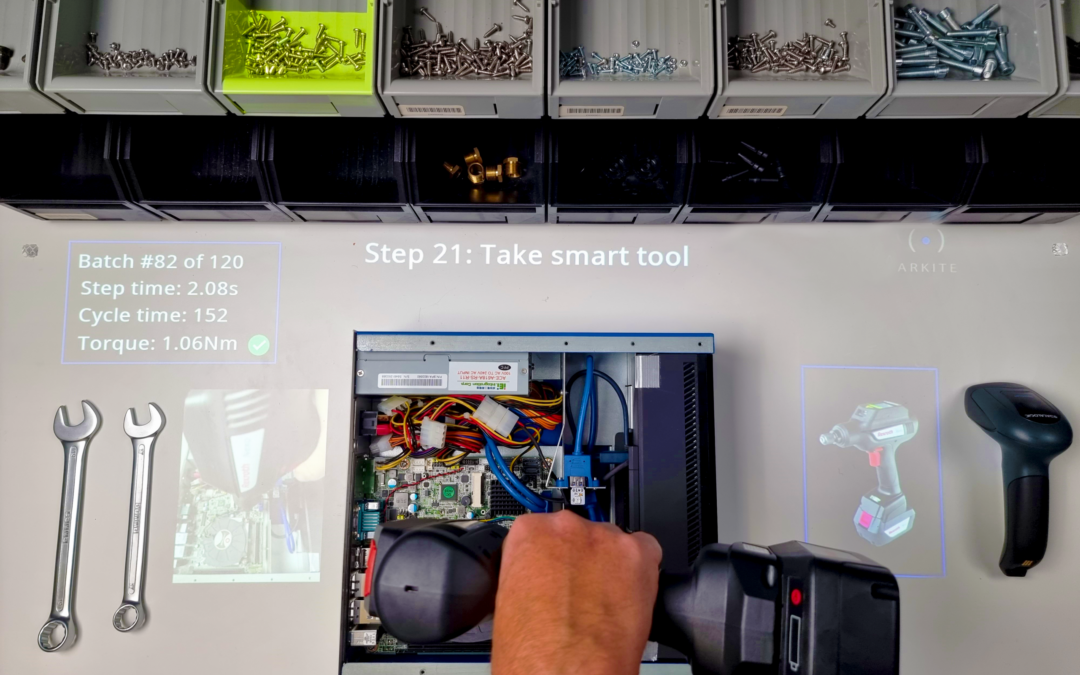

During this webinar we will show why projected augmented reality work instructions are the future in manufacturing. With our Operator Guidance Platform we transform any workstation into a digital and interactive environment by:

The importance of a standardized work environment, and how to achieve and maintain it

Lean Manufacturing, 5S, SixSigma... they all refer to manufacturing philosophies aimed at optimizing production processes by increasing efficiency and eliminating scrap, rework, and waste of time or resources.Some of the main principles that are applied in these...

Arkite and Bosch Rexroth France signed a partnership

Bosch Rexroth France joins forces with Belgian company Arkite to develop the connected workstation of the future Thanks to its cutting-edge technologies, Bosch Rexroth supports all companies in their industrial challenges. Its strength: simplifying the transformation...

5 Challenges in production and how to solve them

Are you also facing ever greater challenges in your manufacturing process? Do you find it difficult to focus on the right tasks to optimize your lean manufacturing? Are you constantly looking for the right balance between maximizing automation and keeping workers...

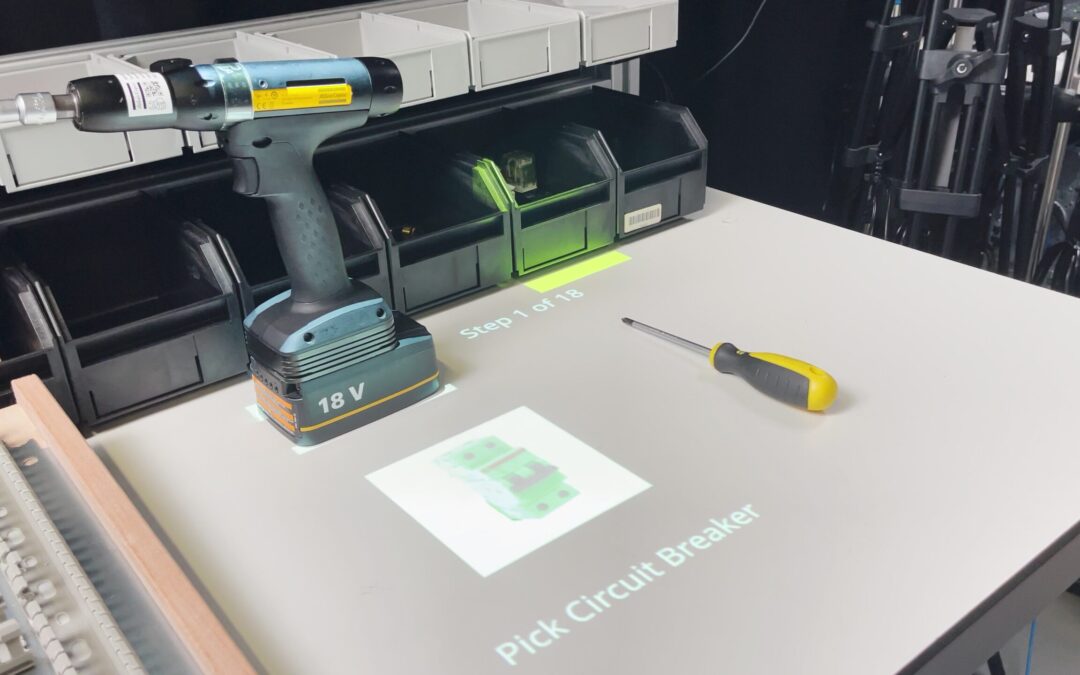

Augmented reality work instructions for manual assembly

Digital Work Instructions and why you should choose for Augmented Reality to implement them Since you’ve come across this website, chances are great you are in the manufacturing industry and you are considering to digitize your workstations. Congratulations, you have...

Virtual reality on the verge of a major breakthrough

Both virtual reality (VR) and its big brother augmented reality (AR) have been enjoying the status of the next big thing for some years now. In the gaming sector, of course, but gradually also on the shop floor. While both technologies are slowly but surely conquering...

How Digital Work Instructions and Operator Independence can go hand in hand

Arkite’s operator guidance platform transforms workstations into a digital and interactive environment by: Guiding your operator with real-time picking and assembly instructions through augmented reality (AR) Validating your operations with our embedded smart-sensor...

![How to transform your workplace into a digital and interactive environment? [SPANISH]](https://arkite.com/wp-content/uploads/LinkedIn-Webinar-Agfra-13_01_2021-1-1080x627.png)

How to transform your workplace into a digital and interactive environment? [SPANISH]

Our Human Interface Mate will help you in several ways to: Guide your operators with Augmented Reality Validate your operations with our embedded smart-sensor Integrate your eco-system to create smarter workstation Convert your manual operations into knowledgeable...

3 Trends for Adaptive Support

During this live webinar our research manager Kim Rutten will show you why Human centered production needs adaptive support systems. Don't miss out on this opportunity! Register now for our latest webinar to discover the newest trends!

How to transform your workstation into a digital and interactive environment – August 25, 10AM CEST

Our Human Interface Mate will help you in several ways to: Guide your operators with Augmented Reality Validate your operations with our embedded smart-sensor Integrate your eco-system to create smarter workstations Convert your manual operations...

Supercharged Supply Chain

Supercharged Supply Chain: Arkite Transforms The Traditional Assembly Line Into A Human-Centered Supply Chain If you’ve ever bought a ready-to-assemble bookshelf or put together a child’s birthday gift, you already know what it’s like to work on an assembly line at an...